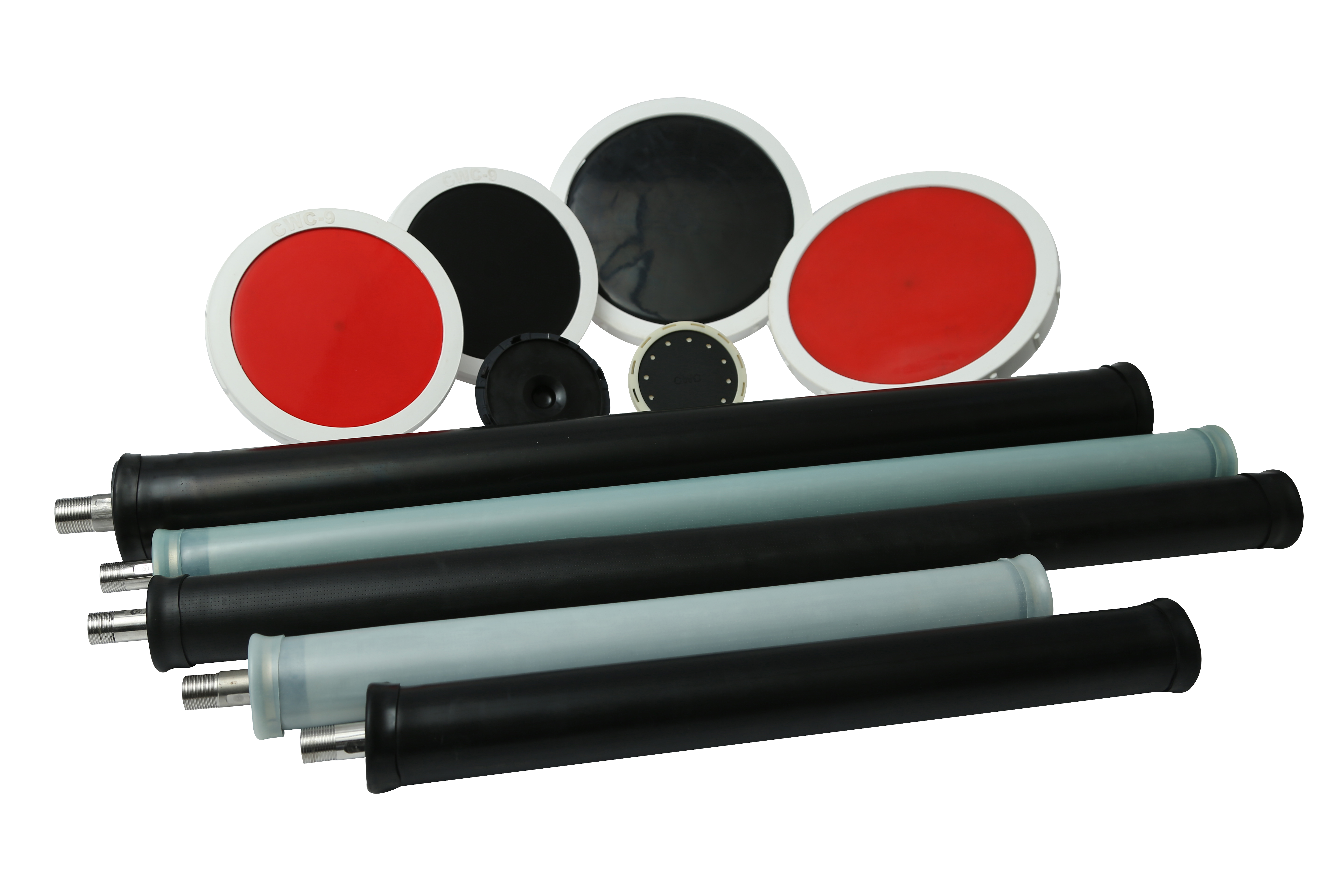

AIRFLEX-Disc Diffuser

AIRFLEX range of products includes a wide range of aeration products as fine bubble and Coarse bubble membrane diffuser-Tube type and Disc type diffuser. The AIRFLEX Membrane Diffuser is manufactured from high Grade EPDM

sleeves, environmentally resistant and durable molded PVC base

PROCESS

In the waste water treatment process, Aeration, to be effective, must transfer oxygen to the liquid for use by microorganism, to produce a floc and mixing the liquor. Diffused aeration is effective method for aeration by means of porous diffusers installed at the bottom of the tank, in the aeration process, oxygen transfer takes place by molecular diffusion through the interface film between air and liquid and it increases in proportion to the interface area. For a given air flow, as the number of bubbles increases, the surface area increases and the rise velocity of bubbles decreases, the diffused aeration transfer more surface area to the liquid than mechanical aeration, e.g. diffuser emerging up to 2 mm bubbles presents six times more surface area to the liquid than surface aerator emitting 10 to 12 mm bubbles, also rise velocity of bubbles is lower. Surface area and rise velocity of bubbles contribute to the higher oxygen transfer capacity of diffused aeration system.

AIRFLEX FINE BUBBLE EPDM MEMBRANE DISC DIFFUSER DISC-245 / DISC-330

MODEL |

DISC-245 |

DISC-330 |

Material of Membrane |

EPDM |

EPDM |

Disc Base |

PP |

PP |

Dia. Of Disc (mm) |

245 (9˝) |

330 (12˝) |

Air Flow (M3/H) |

1.0-7.2 |

1.0-12.0 |

Bubble Size (mm) |

1-3 |

1-3 |

Floor Coverage (%) |

2-25 |

2-25 |

Weight (kg) |

0.60 |

0.85 |

Operating temp.(˚C) |

85 |

85 |

End connection |

3/4˝ BSP Male thread |

3/4˝ BSP Male thread |

Perforated Area (M2) |

0.032 |

0.061 |